Specialty medical needles are essential to the success of an increasing number of medical procedures, including minimally invasive medical procedures. They are also essential components in some of the most innovative medical devices currently being developed.

Sharpness, durability, and precision are critical characteristics of specialty medical needles. Specialty medical needles should also typically minimize penetration force (the ability to penetrate tissue), deflection (the deviation from a straight path of insertion), and tissue damage (helping the healing process).

This brief guide to specialty medical needles will introduce you to the other components, features, and characteristics that you should consider and, ultimately, specify for your medical device product.

Specialty Medical Needle Examples

- Biopsy needles – including fine-needle biopsies (using a thin and hollow needle to aspirate fluid and tissue from the tumor) and core needle biopsies (using a larger needle that enables the removal of a core of tissue from the tumor).

- Coaxial needles – typically a two-needle set comprising a guiding needle on the outside and a biopsy needle on the inside.

- Introducer needles – to provide additional support for the introduction of other devices, such as guidewires or the fine needles used in spinal anesthesia and similar procedures.

- Drainage needles – designed to drain fluid and other material from the body, including abscess collections.

- RF probes, denervation needles, and similar devices – the needle part of medical devices designed to use radiofrequency (RF) energy to perform medical procedures, including cardiovascular procedures, cancer therapies, and radiofrequency ablation (a pain management treatment).

- Brachytherapy needles – needles designed to facilitate brachytherapy procedures where radioactive implants or other materials are inserted into or close to cancerous tissue.

- Pneumo needles and Veress needles – needles used in devices that create pneumoperitoneum in laparoscopic surgeries.

- Tuohy needles – needles that are hollow and have a curved tip often used for epidural catheter insertion.

- Spinal needles – needles designed for spinal procedures, including the injection of anesthetic and for diagnostic procedures.

- K-wires and Steinmann pins – wires or pins that stabilize bone fragments in orthopedic surgeries.

- Suture retrievers – to assist the passing of sutures through soft tissue and bone.

Materials Used in Specialty Medical Needles

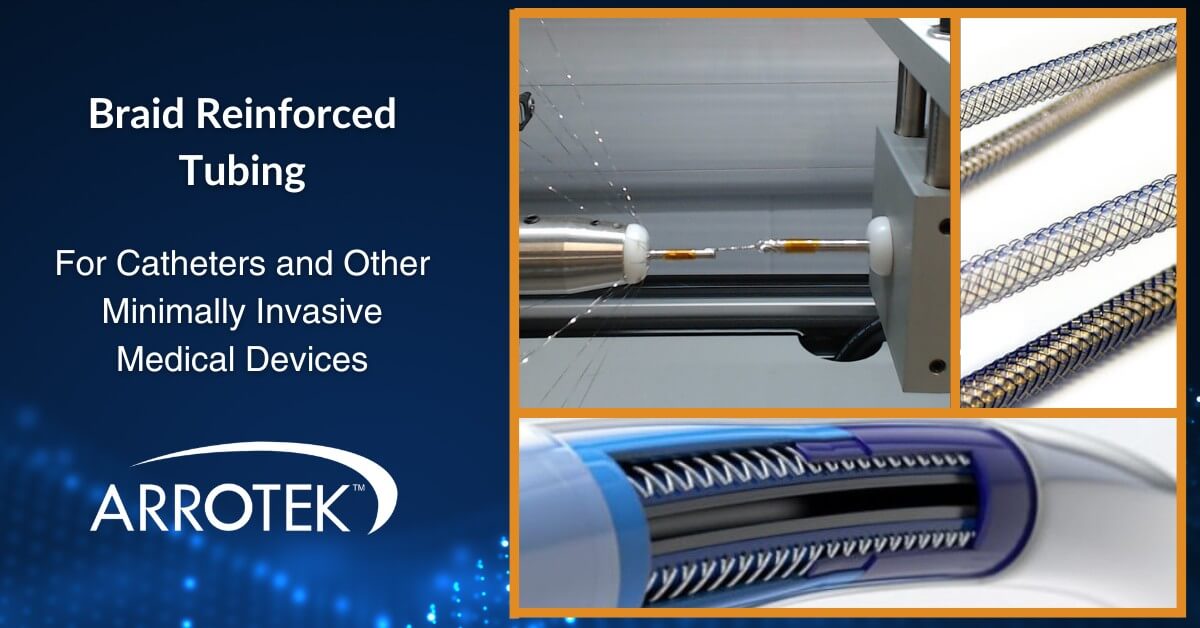

Specialty medical needles are often manufactured from metals, but devices can also include polymers, composite materials, and other materials and components depending on specific application requirements. Examples of application requirements include hardness or the need for braid or coil reinforcement.

Specialty Medical Needle Sizes

Gauge is the standard unit of measurement for specialty medical needles. The needle sizes typically used in medical procedures range from 7 gauge to 28 gauge. Finer and smaller needles have a higher gauge number, so a 28-gauge needle has a smaller diameter than a 7-gauge needle.

The correct size of needle depends on the application. As a general rule, needles for subcutaneous injection should be 19 gauge to 27 gauge and are typically small in diameter. Longer and thicker needles are often required for intramuscular injections, with common sizes between 20 gauge and 22 gauge. Intradermal injections usually require needles at the smaller end of the scale, often between 26 gauge and 28 gauge.

The international standard ISO 6009 outlines a color coding for needle hubs. This ensures the size of the needle can be easily identified by the color of the hub.

Common Parts and Features of Specialty Medical Needles

- Handles, hubs, and luers – there are common configurations, but customized designs are also possible.

- Shaft materials and design – manufactured from metals, polymers, or composite materials with designs that can be curved or bent according to requirements.

- Coring or non-coring – coring needles are used to remove a core of tissue, such as in a core needle biopsy procedure.

- Cannulas, trocars, and stylets – often used with a trocar needle, a cannula is a plastic tube longer than a needle and can be used for a range of purposes, including the delivery of fluid, removal of fluid, or the collection of samples. Stylets are commonly used to keep catheters open and are typically inserted into the cannula.

- Echogenic markings – a range of marking options to make the needle more visible to the clinician using ultrasonic guidance.

- Needle points – high-precision tips with complex point geometries and optimized levels of sharpness. Commonly used point geometries for specialty needle bevels include Primary, Pencil, Chiba, Madayag, Lancet, Spade, Menghini, Trocar, and Franseen.

- Packaging – tip protection packaging as well as standard packaging considerations, including transport protection, labeling, and ease of use.

Specialty Needles From Arrotek

We offer a comprehensive range of specialty needle expertise at Arrotek along with extensive experience in the industry. This includes turnkey design, development, and manufacturing expertise.

Our capabilities cover needles and their associated devices from the handle to the tip, including additional components that are part of your medical device product.

Our manufacturing and process capabilities include:

- Product design, development, and customization

- Regulatory support

- CNC machining, milling, and turning

- Electro-chemical cutting and grinding

- Electrical discharge machining (EDM)

- Needle point grinding

- Metal machining and fabrication

- Injection molding and insert molding

- Laser processing

- Cleaning and finishing

- Metal forming

- Sterilization

- Assembly and packaging

- Metal finishing

- Rapid prototyping

To discuss your requirements for specialty needles or any other aspect of your medical device product or project, please contact us at Arrotek today.