Advanced Catheter Technologies

Catheter Design and Development Expertise

At Arrotek, we can minimise the time it takes to get your catheter device market ready. We have extensive design and engineering experience in Advanced Catheter Technologies, particularly in relation to devices with ultra-thin walls. We also have in-house prototyping and manufacturing capabilities.

In other words, when you choose us at Arrotek, you’ll be partnering with a fully equipped team that is ready to hit the ground running with your catheter development project.

Design Innovation

Our design team specialises in minimally invasive medical devices, particularly Advanced Catheter Technologies with ultra-thin walls. We use a six-step design process to bring your catheter device from concept stage to prototype stage, pilot production, and beyond. We also have extensive regulatory expertise and will ensure compliance is a central part of the design process from beginning to end.

Ultra-Thin-Walled Catheter Solutions

At Arrotek, we have expertise in developing ultra-thin-walled catheter devices with wall thicknesses as low as 0.1mm (0.004’’).

Our in-house capabilities include design, prototyping, and manufacturing, enabling the development of new catheter solutions that improve diagnostic capabilities, treatments, and patient outcomes.

Manufacturing Capabilities

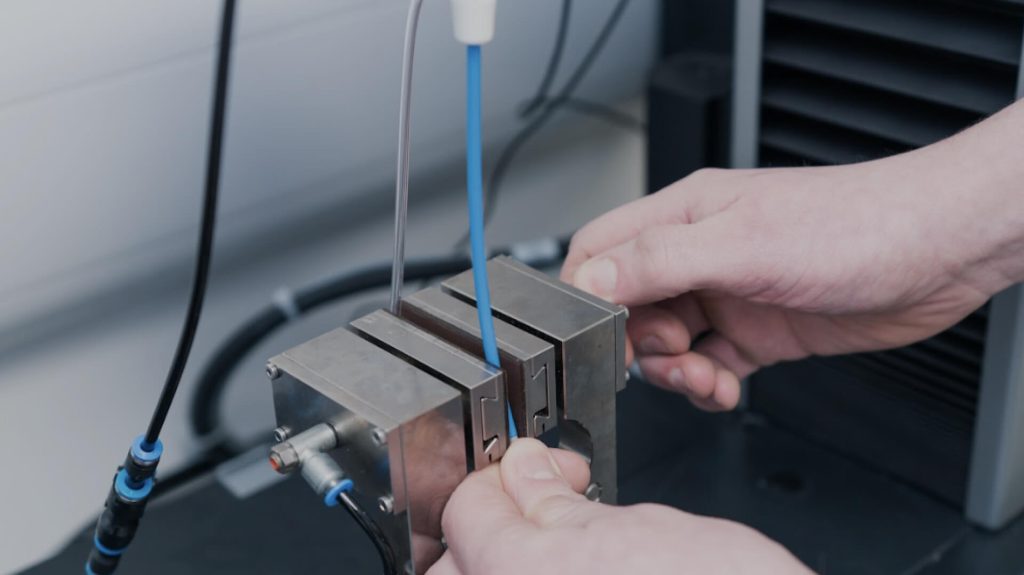

We are fully equipped at Arrotek to manufacture minimally invasive medical devices with specialist machines in our well-equipped manufacturing facilities in the USA and Ireland. This includes coiling and braiding machines for thin-walled polymer tube reinforcement.

Braiding & Coiling Expertise

The production of a prototype for your new medical device will take place in-house in our modern manufacturing and engineering facility.

We have a range of prototype production capabilities suitable for the development of Stage 1 prototypes for design review and concept enhancement, and Stage 2 prototypes for functional evaluation and testing.

Innovative Catheter Technologies

- Coil and braid reinforcement – suitable for a range of applications, both therapeutic and diagnostic, to achieve advanced performance characteristics, such as ultra-thin walled tubing, reduced shaft profile, improved flexibility, better kink resistance, and enhanced torque control.

- Metal Shafts and Hypotubes – designing and developing innovative metal shaft and hypotube solutions, including for PTCA catheters, intravascular imaging devices, and

- Other specialist catheter devices.

- Wire and Coil – wire-based delivery systems and guidewires for both neurovascular and cardiovascular devices.

- Extrusions – we can develop a custom extrusion solution for your catheter device. We have extensive knowledge of materials to achieve precise tolerance requirements with minimal wall thickness.

- Balloon catheters – the development of balloons with precise tolerances that achieve optimal levels of performance. We have experience working with a range of materials, including non-compliant, semi-compliant, and compliant materials. We also have experience in both PTCA and PTA applications.

- Moulding – capabilities and experience to deliver on the moulding and insert moulding requirements of your catheter device. This includes catheter tips, bifurcated and mono luers, rapid exchange joints, multi-lumen joiners, multi-exchange joints, Y-connectors, and strain reliefs. We can also help design, develop, and manufacture deployment handles and assemblies.

From Our Knowledge Hub