By Richard McLoughlin

Guidewires are an important tool used by clinicians in a range of procedures, so they are a crucial component of many minimally invasive medical devices. Guidewires also come in multiple configurations with a vast range of performance and functional characteristics. How do you choose the right guidewire for your medical device?

The default in many situations is to go for a workhorse guidewire. In fact, clinicians often have a favored workhorse guidewire. This isn’t always the best option, though.

By understanding the key technologies, materials, and design features of interventional guidewires, the best and most effective solution can be selected to match the intended use of your medical device.

Focus on the Operator’s Clinical Requirements

When choosing an interventional guidewire for your medical device product, it is important to focus on the user who, in most cases, will be a clinician who sub-specializes in cardiovascular, peripheral vascular, or neurovascular procedures. What are their clinical preferences for the target indication? What are the design requirements of the guidewire device? What are the main challenges of the procedure/s described in the intended use definition of the medical device?

Understanding the perspectives and priorities of the clinicians who will be using your medical device product is an important step in choosing the right guidewire solution.

The Importance of Tactile Feel

Tactile feel is arguably the most important performance characteristic that clinicians look for in a guidewire. High levels of tactile response as the guidewire passes through complex vasculatures helps clinicians navigate past obstructions to reach the target location.

Understanding Performance Characteristic Compromises

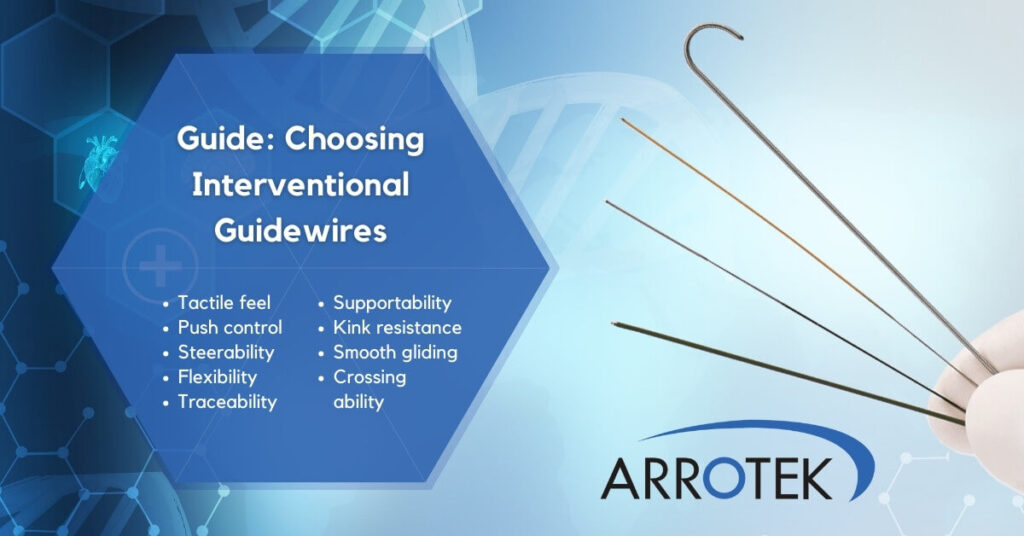

There are multiple performance characteristics that apply to interventional guidewires, including:

- Push control

- Steerability

- Torque control (responsiveness to rotational force applied by the clinician)

- Flexibility

- Opacity and traceability

- Supportability

- Kink resistance

- Smooth gliding through vessels

- Crossing ability (the ability of the guidewire to cross a lesion)

However, it is not possible to get a guidewire that does everything and ticks all the above performance characteristic boxes. Compromise is, instead, necessary, where you compromise on one performance characteristic to enhance another.

An example is the smooth gliding of a guidewire through vessels, a performance characteristic that is often achieved with lubricity features. However, high levels of lubricity reduce tactile feel, so there needs to be a compromise.

Another example is stiffness versus flexibility. A flexible guidewire makes it easier for clinicians to navigate to the target location, particularly through tortuous vasculatures. With flexibility, however, you often reduce the support characteristics of the guidewire, again highlighting the need for compromise.

Other Key Features of Interventional Guidewires

The main interventional guidewire features to be aware of include:

- Core diameter – the overall diameter of guidewires is important, but this feature refers specifically to the diameter of the core element of the wire. This element typically tapers at the tip. Core diameter primarily impacts flexibility, support, and torque control.

- Core taper – how the core of the guidewire tapers at the tip. Core taper also impacts torque control, as well as the ability of the guidewire shaft to follow the tip as it navigates bends.

- Core material – the main materials used in guidewire cores are stainless steel (which helps with torque control, push control, and support) and nitinol (for flexibility and kink resistance). It is also possible to have hybrid guidewires with nitinol tips and stainless-steel shafts.

- Tip design – the design of the tip is essential for navigation and traceability, as well as preventing the accidental perforation of vessels.

- Tip load – the strength of the tip and its resistance to bending.

- Coils – coils added at the tip of the guidewire help it retain its original shape while it is navigating through vessels.

- Coatings – hydrophilic coatings increase the guidewire’s lubricity and reduce friction.

- Radiopaque markings – radiopaque markings are often added to guidewire tips to make them more visible using fluoroscopic imaging.

- Guidewire length – the length required to reach the target location.

Expert Advice and Support on Guidewires at Arrotek

At Arrotek, while we manufacture custom specialty needles, cannulas, stylets, and similar steel components, we also offer additional expertise in the design and manufacture of interventional stainless steel and nitinol guidewires (.010 to .038 diameter), including value-added services such as hydrophilic coating, packaging, sterilization, and regulatory support. If you have a query about guidewires or anything else in relation to your minimally invasive medical device, please complete the form below and a member of our team will get back to you.