Manufacturing Capabilities

Manufacturing for Medical Devices

With our extensive experience in manufacturing medical devices, we can help with your requirements. Browse our capabilities in the sections below or contact us to discuss your medical device manufacturing needs.

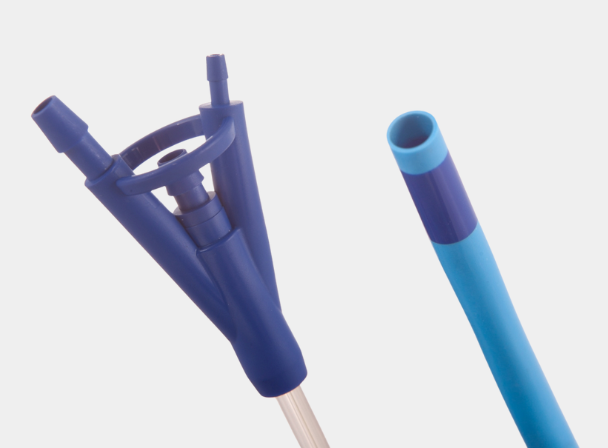

Balloon Blowing

Tipping

We have extensive experience of induction heating processes and are capable of tipping tip lengths of up to 100mm in a range of materials including nylon, PE, PU, PEEK, and fluoropolymers. We design all tooling in-house to reduce lead times and offer you a more efficient service.

Inject/ Insert Moulding

We have high-quality, modern, and efficient injection moulding equipment in our Class 8 (100,000) cleanroom. We use this equipment to manufacture both prototypes and production builds. In addition, we work with local toolmakers to minimise turnaround times and deliver on your requirements.

Bonding

Using our expertise, we’ll select the correct bonding method suitable for your medical device. This could be heat welding two similar materials, for example, or using an adhesive. Our team will develop a tailored process that suits your requirements.

Printing

Using a closed cup pad printing system, we offer consistent print detail and can print graduation marks and logos. Plus, we have developed a biocompatible surface treatment process that allows us to print on a wide range of materials.

Film Welding

We have developed in-house film welding technologies so can create any size of film weld necessary for your application. Our capabilities include producing both large and small-volume balloons depending on the requirements of your medical device.

Coiling and Braiding

We have both coiling and braiding capabilities in-house to enhance the performance characteristics of your device. Our capabilities include variable braid pitches, braid over coil, braid over braid, and braid over coil transitions.

Thermal Processing

Our thermal processing capabilities allow us to transform metals, polymers, and other materials, altering their chemical properties. This can enhance the mechanical and thermal properties of your device and improve quality.

CNC Machining, Milling, & Turning

We utilise the highest level of accuracy and attention to detail provided by our CNC machines to guarantee superior quality component manufacturing. We can produce tight tolerances on complex parts and precision engineering of complex geometry.

Electro-Chemical Cutting & Grinding

Our electro-chemical cutting and grinding capabilities mean we can machine the most difficult materials regardless of their hardness or strength. It is a low stress machining operation that eliminates the risk of damage and can be carried out on both thin and thick materials.

Laser Welding

We have considerable laser welding experience with the ability to laser weld various materials commonly used to manufacture components for medical devices. This includes nitinol and stainless steel.

EDM Drilling

Our Electrical Discharge Machining capabilities enable us to precision drill and plunge form holes and other shapes on medical device components.

Needle Point Grinding

We use a wide range of grinding systems to produce various needle point geometries with high levels of precision and quality.

Metal Machining and Fabrication

Our metal machining and fabrication capabilities include CNC milling, automated swaging, tumbling, catheter tipping, laser cutting, laser welding, and ultrasonic welding.

Laser Processing

Our laser processing capabilities include laser cutting, laser welding, and laser engraving.

Fixtures & Tooling

Our in-house fixture and tooling manufacturing capabilities reduce lead times and costs while ensuring consistent quality and optimum flexibility. Our in-house fixture and tooling capabilities are a crucial component of our design transfer process.

Cleaning and Finishing

Our capabilities include a range of cleaning and finishing processes, particularly for metal components, including electro-polishing, electro-etching, tumbling, automatic passivation, oven drying, and spin-drying.

Finished Product Assembly

By combining the above processes, we can offer full assembly services to produce your finished product. We also have additional capabilities in-house that you might need for your product. This includes tray and pouch sealing as well as the option to fully pack. We can also coordinate all sterilisation and logistics activities to make your device ready for distribution.

Lubricious Coatings

We can apply lubricious coatings to catheters or guidewires to significantly reduce the coefficient of friction of the device. Our expertise and capabilities include both hydrophilic coatings and hydrophobic coatings.

Packaging & Labelling

We offer a range of packaging solutions, including custom packaging and labelling. We can supply products in a bulk non-sterile configuration or single-packed sterile with custom labels.

Sterilisation

We can supply your product in a sterile or non-sterile condition. A range of sterilisation options, including Ethylene Oxide (EtO) sterlisation is available depending on your device and other considerations.

Regulatory & Design Control

We offer full regulatory and design control support, including 510(k) applications and applications under the EU MDR. Our expertise and capabilities also include Design History Files, Device Master Records, technical dossiers, and clinical complaint management / failure analysis.

Continuous Improvement

We continuously invest in our equipment, processes, and skills to ensure continuous improvement in manufacturing for medical devices. This includes improvements in costs, quality control, safety, reliability, supply chain management, and oversight.