Micro Needles

Micro Needle Solutions and Capabilities

Micro needles provide versatile solutions across various industries, offering innovative, minimally invasive approaches for medical, cosmetic, and diagnostic needs. Key applications include:

- Drug Delivery: Enabling efficient delivery of medications, such as vaccinations, diabetes management, and cancer therapies.

- Cosmetics & Skincare: Enhancing treatments like micro-needling for skin rejuvenation and scar reduction.

- Ophthalmic: Facilitating intraocular drug delivery and promoting corneal regeneration.

- Transdermal Diagnostics: Allowing for continuous glucose monitoring and advanced biomarker analysis.

Micro Needle Manufacturing Expertise

At Arrotek, we specialize in the precise manufacturing of micro needles, ensuring high-quality, custom solutions for every application. Our advanced capabilities include:

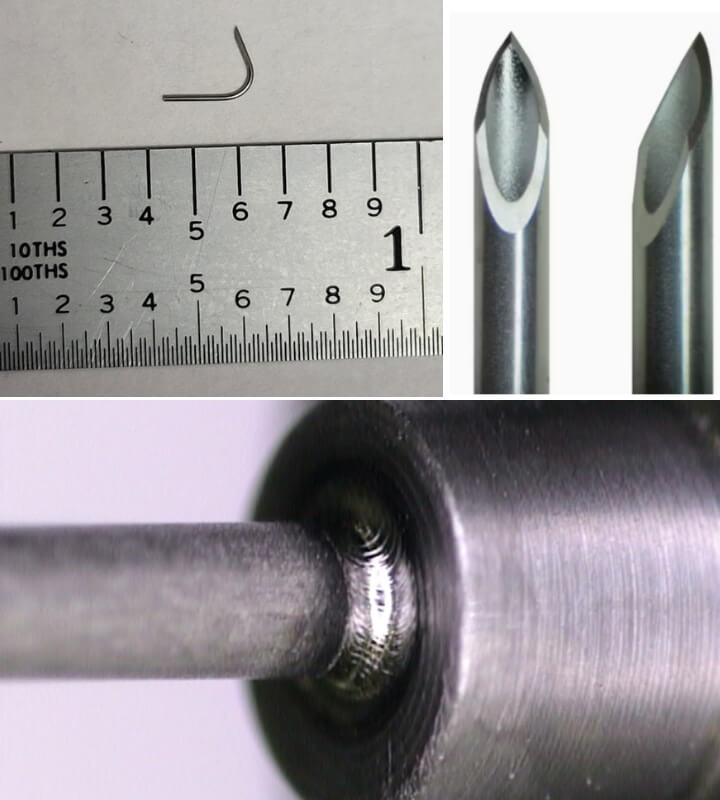

- Pointing: Precision grinding and laser cutting, capable of producing up to 4 million parts per year in sizes as small as 32G.

- Bending: Custom bend geometries tailored for your specific application needs.

- Laser Welding: Creating high-strength, leak-free joints for durable and reliable micro needle components.

- Cleaning & Passivation: Removing contaminants and reducing surface contamination to ensure product safety and effectiveness.

- UV Gluing: Offering high-precision component joining with UV-cured adhesives for enhanced strength and durability.

Customized Micro Needle Tip Geometry

Arrotek specializes in designing micro needle tips with tailored geometries to meet the specific requirements of each application. Examples include:

- 30G 30-Degree Straight Bevel

- 29G Laser Cut Curve

- 32G 26-Degree Lancet

We can customize the geometry of the needle tips to provide the optimal solution for your project.

Micro Molding Capabilities

Our in-house molding capabilities are designed to produce a variety of standard molded components. Additionally, we partner with trusted experts for the design and fabrication of small-form molded parts. We can accommodate shot volumes ranging from 1.2 to 6 cm³, ensuring precise and efficient production of parts.

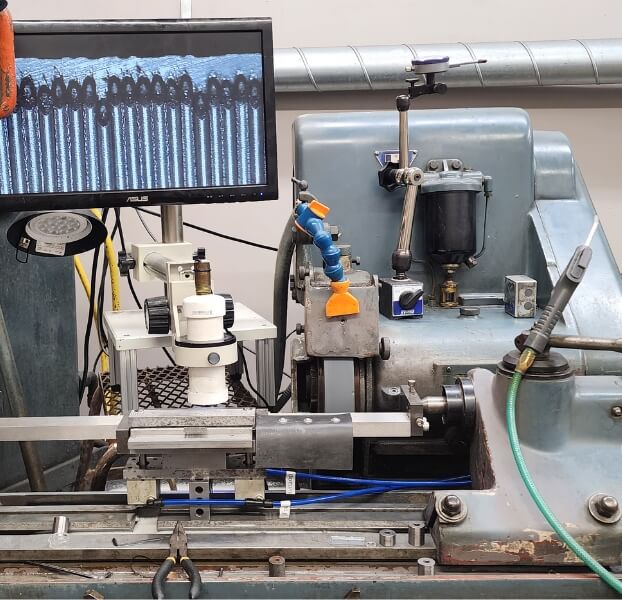

Research and Development (R&D) Capabilities

Arrotek is committed to advancing our micro-machining and manufacturing techniques to stay at the forefront of innovation. Our R&D efforts include:

- Investment in state-of-the-art grinding machines to develop custom fixtures and optimize processes.

- Rapid prototyping capabilities for quick turnaround of prototype parts to support customer testing and validation.

Let us help you bring your micro needle solutions to life with precision, reliability, and efficiency.