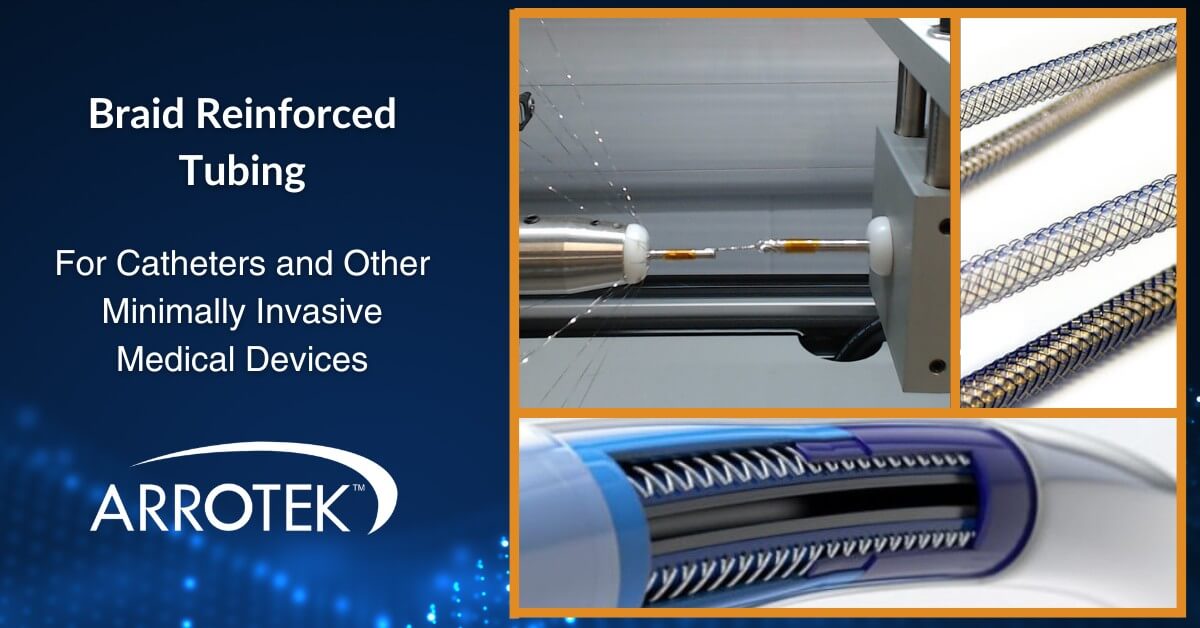

There are two main types of tubing reinforcement for catheters and other minimally invasive medical devices – braid reinforcement and coil reinforcement. While there is often a crossover between the two, we are going to focus on braid reinforcement in this article.

Advanced catheter technologies and other minimally invasive medical devices continue to transform healthcare, including in the most complex of procedures. Braid reinforcement is a crucial component of many of these innovative medical devices, as the braid-reinforced layer of the tube enhances its performance.

For example, braid reinforcement enables the use of ultra-thin wall tubing. It is also suitable for multi-lumen and multi-durometer applications, and it enhances the capabilities of steerable and deflectable catheters. Braid-reinforced tubing is also often used in catheter devices where there is a requirement to integrate other technologies, such as hydraulics or optics.

As a result of these capabilities, braid-reinforced tubing is suitable for a range of diagnostic and therapeutic applications:

- Heart valve and stent delivery systems, as well as other cardiovascular applications

- Neurovascular applications

- Endoscopic applications

- Biopsy devices

- Ablation catheters

- Electrophysiology catheters

- High-pressure tubing

- And more

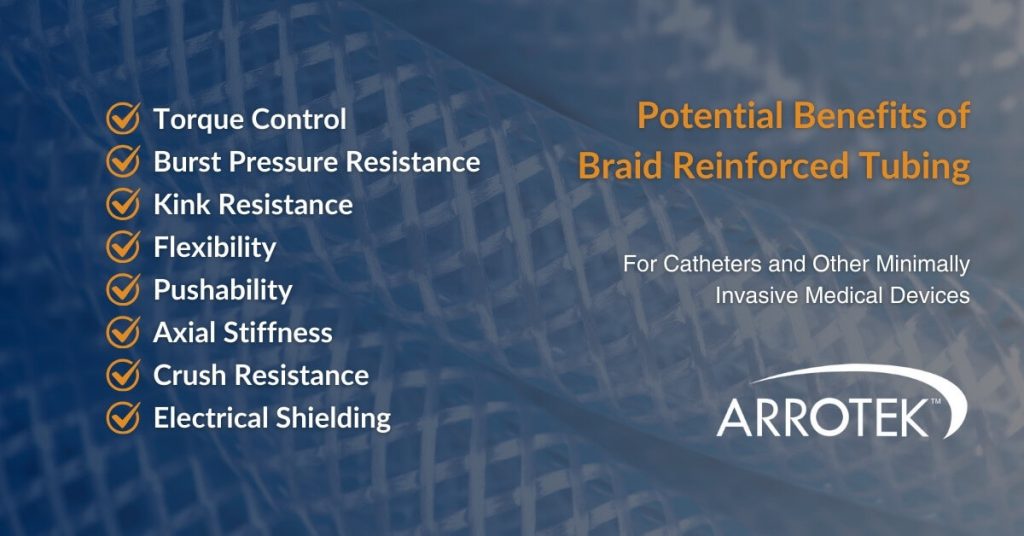

Benefits of Braid Reinforced Tubing in Catheters and Other Medical Devices

There are two main benefits that reinforced tubing brings to a catheter:

- Improved torque control

- Improved pressure resistance

Improved torque control is often regarded as the most important benefit, as torque control makes the catheter easier to maneuver and position in the body. Specifically, torque control improves the pushability and steerability of the catheter as it is guided through a body’s anatomy.

Additionally, improved torque control and burst pressure resistance together make braid-reinforced tubing suitable for catheters that need to navigate tortuous vasculatures. Other benefits of braid-reinforced tubing include flexibility, kink resistance, axial stiffness, crush resistance, and electrical shielding.

Braid Reinforced Tubing – a Design Overview

Layers

Braid-reinforced tubing has three layers:

- Inner liner

- Braid reinforcement layer

- Outer jacket

The inner lining and outer jackets can be made from almost any thermoplastic or fluoropolymer. PTFE is a common choice for the inner layer because of its high levels of lubricity and because it is suitable for both thin wall and multi-durometer designs. However, FEP, ETFE, HDPE, Pebax, and other materials are also used.

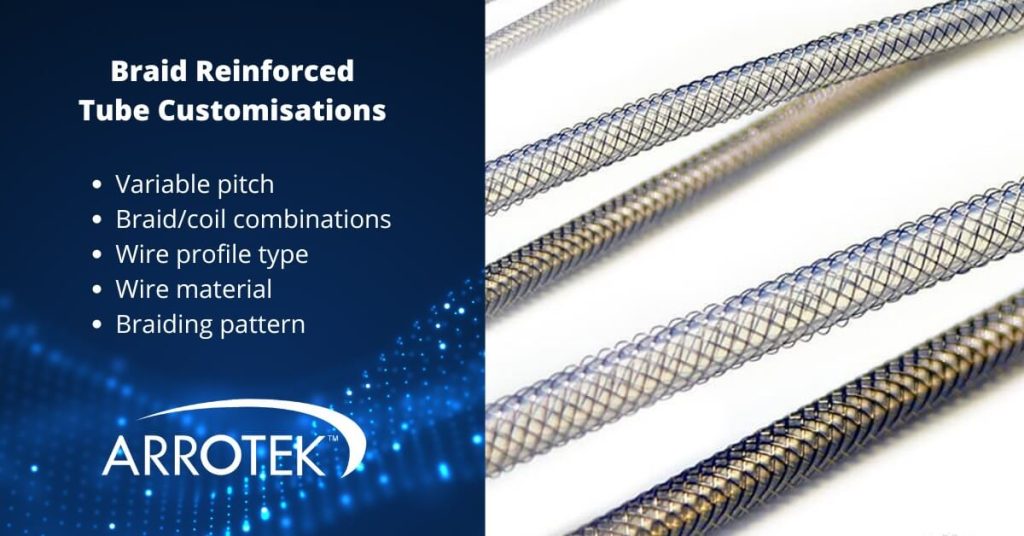

Braid Reinforced Layer

In terms of the braid-reinforced layer, shafts can be braided in multiple ways. Examples of reinforcement options include varying the pitch of the braid along the length of the tube. The pitch of a braid-reinforced layer refers to the number of times a wire crosses over a set distance, usually one inch. This is often referred to as picks per inch of length or PPI.

A high PPI means more wire coverage along the shaft and typically results in enhanced column strength and torque control. A lower PPI, on the other hand, can improve kink resistance. Variable pitch options are also possible, with pitch differing along the length of the shaft to achieve the desired performance characteristics.

The shaft can also be reinforced using a combination of braid and coil reinforcement:

- Braid over coil reinforcement

- Braid over braid reinforcement

- Braid to coil transitions

Different types of wire can be used to create the braid-reinforced layer, including round, flat, and ribbon wires. The right option will depend on the application and performance requirements of your medical device.

Materials Used in Braid Reinforcement

Braid reinforcement is often manufactured using nitinol, but it can also be manufactured with stainless steel, fabric, Kevlar, platinum, and a range of other materials.

Various considerations are taken into account when deciding on the most suitable material for the braid reinforcement of a shaft, including the performance characteristics required by the device and whether it needs to be MRI and X-ray-compatible. Stainless steel and nitinol, for example, are not MRI or X-ray-compatible.

In applications where MRI or X-ray compatibility is not required, stainless steel is a common choice. However, nitinol can enhance kink resistance, so it is more suitable for certain applications.

Optimising the Design of the Reinforced Tube

As already highlighted, braid-reinforced tubing in catheter devices improves torque control. However, it is possible to enhance the performance characteristics of the shaft in other ways by adjusting the design of the braid-reinforced tubing. Examples include:

- Wall diameter

- Tube profile

- Flexibility

- Kink resistance

- Torque control

- Burst pressure resistance

- Pushability

- Axial stiffness

- Crush resistance

- Electrical shielding

Wall Diameters

By using a braid and coil combination for the reinforcement layer of the shaft, it is often possible to reduce the thickness of the tubing’s wall.

Overall Profile of the Tube

Using flat wires for the braid-reinforced layer will reduce the overall profile of the shaft compared to using round wires, although there is likely to be a reduction in shaft flexibility with the use of flat wires.

Flexibility

The flexibility of braid-reinforced tubing can be refined using a range of different methods. For example, you can use a combination of coil and braid reinforcement rather than braiding on its own, or you can vary the durometer along the length of the shaft.

Varying the braid’s pitch can also adjust the shaft’s flexibility while at the same time improving torque response.

Different braiding patterns can have a similar impact on the performance characteristics of the device. Commonly used braiding patterns for braid-reinforced tubing include:

- Diamond – 16 wires in a two-under-two, over-two pattern.

- Herringbone, also known as a regular pattern – 16 wires in a one-under-two, over-two pattern.

- Half diamond – one-under-one, over one pattern.

Kink Resistance

Varying the braid’s pitch can improve kink resistance in addition to altering the flexibility and torque response of the shaft.

Torque Control

While braid-reinforced tubing offers enhanced torque control, this performance characteristic can be improved further by using various techniques to design the braid-reinforced layer. For example, a high PPI will increase torque control, as will using higher-diameter braid wires. Creating Highly Customized and Innovative Tubing Solutions Using Braid Reinforcement

Creating Highly Customized and Innovative Tubing Solutions Using Braid Reinforcement

As the above section demonstrates, there is more than one type of braid reinforcement method that can be used in the design of your new medical device. There are also multiple design approaches that can be used to achieve the required performance characteristics for the braid-reinforced tubing.

It is not always necessary to pick one over another either, as it is often possible to combine different design approaches along the length of the shaft. For example, changing the braid pattern along the length of the shaft will alter the stiffness, increasing or decreasing flexibility at various points.

In other words, braid-reinforced tubing makes it possible to create highly innovative catheter technologies and minimally invasive medical devices.

The Importance of Knowledge and Experience

It is also beneficial to highlight the importance of knowledge and experience when it comes to the design of braid-reinforced tubing.

Knowledge and advanced expertise are both invaluable during the design process. They will help you achieve your goals while pushing the boundaries of catheter and medical device product design.

At Arrotek, we have extensive knowledge, experience, and expertise in the design and manufacture of braid-reinforced tubing for a range of applications, including highly innovative catheter devices. We also have an in-house Steeger braiding machine that we use for the full-scale manufacturing of medical devices and the production of prototypes during the design process. To speak to one of our engineers about braid-reinforced tubing or any other aspect of your medical device product idea, please get in touch.