Guide-wires are an essential component of many minimally invasive medical devices, including many advanced catheter products. There are multiple types of guide-wires available, with different technologies, materials, designs, and performance characteristics. In this blog, we’ll look at the essential design features that should be considered when looking at guide-wires for your product.

Guide-wires are designed to navigate often tortuous vasculatures to reach target treatment or diagnostic sites within the body. They are also used in the placement of interventional devices, and they enable the placement of catheter devices while also helping to stabilize and precisely position catheters at the target location.

Therefore, guide-wires are essential to the successful completion of a range of different medical procedures. If you are developing a new catheter or another type of medical device, guide-wires are a crucial component. Here are the essential design considerations that you need to be aware of.

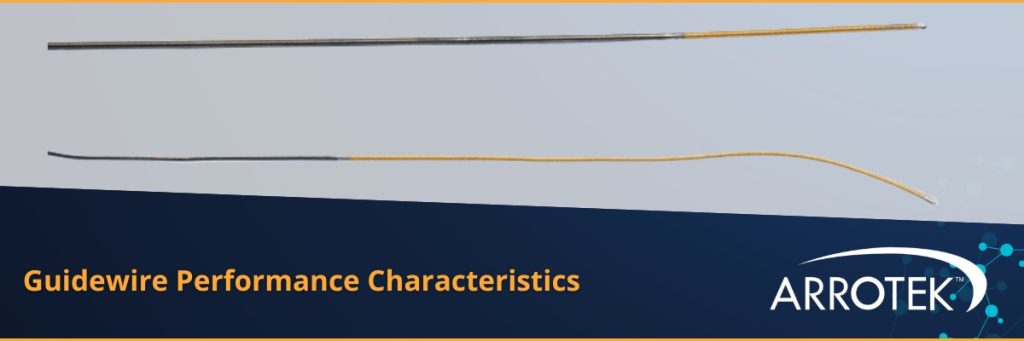

Guide-wire Performance Characteristics

There are a number of performance characteristics that are important when designing or choosing a guide-wire for your minimally invasive medical device.

Push Control

Push control (often referred to as pushability) is the ability to push the guide-wire through vessels to reach the target location.

Steerability

The responsiveness of the guide-wire tip as the clinician steers the guide-wire through the body’s vasculature. Both steerability and push control are part of the guide-wire’s trackability.

Torque Control

Torque control is the responsiveness of the guide-wire to turn inside vessels as the clinician applies rotational force. The ideal objective in most situations is 1:1 torque, where the rotational force applied by the clinician at the proximal end of the guide-wire is translated at a 1:1 ratio at the distal tip.

Flexibility

The ability of the guide-wire to maintain trackability and torque control while flexing on its longitudinal axis.

Opacity

The visibility of the guide-wire to the clinician as it is being navigated through the body to the target location. Visibility is typically achieved under fluoroscopic imaging. For some applications, radiopaque markings are required along the guide-wire to offer enhanced visibility.

Catheter Guide-wire Design Considerations

Guide-wire Tips

The tip is one of the most important components of a guide-wire as the design needs to prevent the perforation of vessel walls while facilitating the navigation of the guide-wire through the required vasculatures.

There are various tip shapes that are possible, including J-curve or straight tips, as well as different levels of rigidity/flexibility. J-tip variations can be designed to straighten when required.

Tip shape retention is a key characteristic for many applications, where the tip can flex while tracking through vessels, before returning back to its original shape.

Core Taper

Guide-wires have two main elements – the core and the tip. How the guidewire’s core tapers to the tip is an important consideration, especially in relation to the length of the core taper. In general, short tapers provide added support while long tapers are easier to track.

Lubricity

The addition of a hydrophilic coating to the guide-wire reduces friction as it is tracked to the target location.

Tactile Feel

High levels of tactile feel make it easier for the clinician to navigate the guide-wire. However, there is often an inverse relationship between tactile feel and lubricity (see the above point on lubricity). Greater lubricity reduces friction as the guide-wire passes through vessels, but it also reduces tactile feedback.

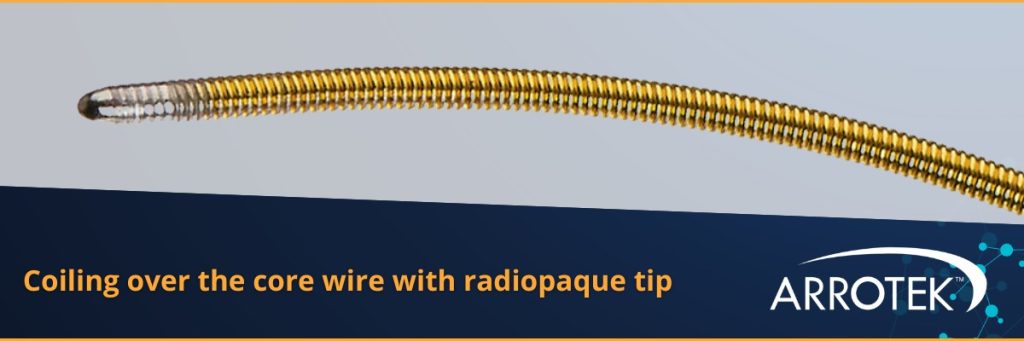

Braiding and Coiling

The addition of braiding or coiling over the core wire increases the flexibility of the guide-wire and improves its ability to return back to shape.

Stiffness Versus Flexibility

Greater stiffness provides more support for the catheter, for example, while greater flexibility enables the navigation of more complex vasculatures. In terms of flexibility, the goal is often to achieve a no-memory effect to ensure there is no pressure on vessel walls during procedures.

Tip Load

The force needed to bend the tip.

Crossing Ability

This is the ability of the guide-wire to navigate obstructions, as well as the ability of the catheter to navigate through or by the same obstacles when being passed over the guide-wire. In other words, it is not enough for the guide-wire to cross the obstruction if the catheter can’t then follow.

Materials

The most common materials used in guide-wires are nitinol or stainless steel. Both offer different performance characteristics. For example, nitinol offers flexibility and kink resistance while stainless steel has excellent torque control characteristics.

Length

How long does the guide-wire need to be to reach the target location?

Diameter

Smaller diameter guide-wires allow for more complex procedures, including those where smaller or more tortuous vessels need to be tracked. Almost all the above guide-wire performance features and characteristics factor into decisions on diameter.

Guide-wire Expertise at Arrotek

At Arrotek, we offer comprehensive design services for catheters and other minimally invasive medical devices. This includes guide-wires and all other components of your product. We can also call on the expertise and product range of our sister company, Galt Medical. Galt manufactures and supplies OEM and private-label guide-wires. To discuss your project in the strictest confidence, please get in touch.